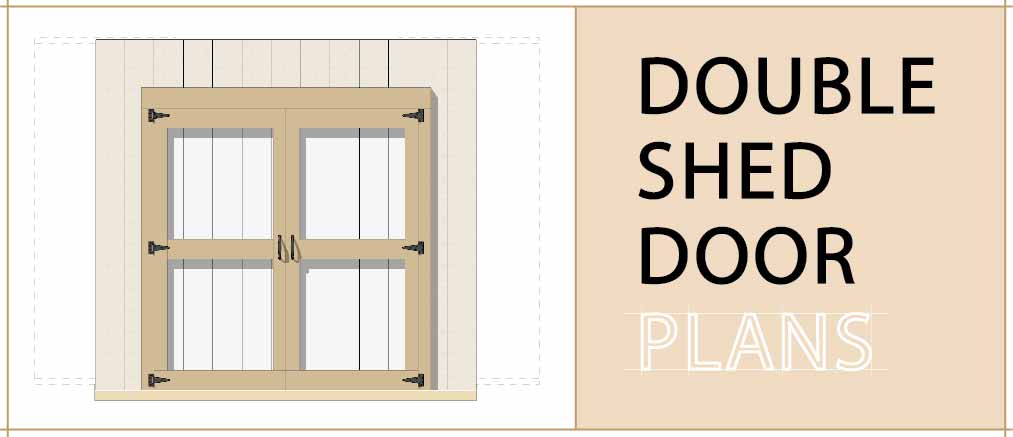

Overview

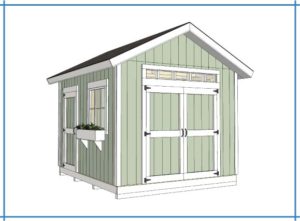

This is a simple method to construct a sturdy and lightweight double shed door. The door height and width can be easily customized per shed size as needed. See instructions here for single shed door plans. This door build fits all shed designs, check out our Shed Plan Library!

Want to add a single door to your shed? Check out our Single Door Plan.

Material and Cut List

DOOR FRAME

2 – 2 x 4 Lumber: 6′-3 1/2″

6 – 2 x 4 Lumber: 7 1/2″

2 – 2 x 6 Lumber: 6′-3″ (door header)

1 – 2 x 6 Plywood Filler: 6′-3″ (door header)

1 – 2 x 6 Lumber: 6′-7″ (door trim)

2 – 2 x 4 Lumber: 6′-5″ (door trim)

DOOR

4 – 2 x 6 Lumber: 3′

2 – 2 x 6 Lumber: 2′ 5″

4 – 2 x 4 Lumber: 5′ 6″

2 – 4′ x 8′ Plywood Siding Panel T1-11: 6′-5 3/4″ x 3′-0″

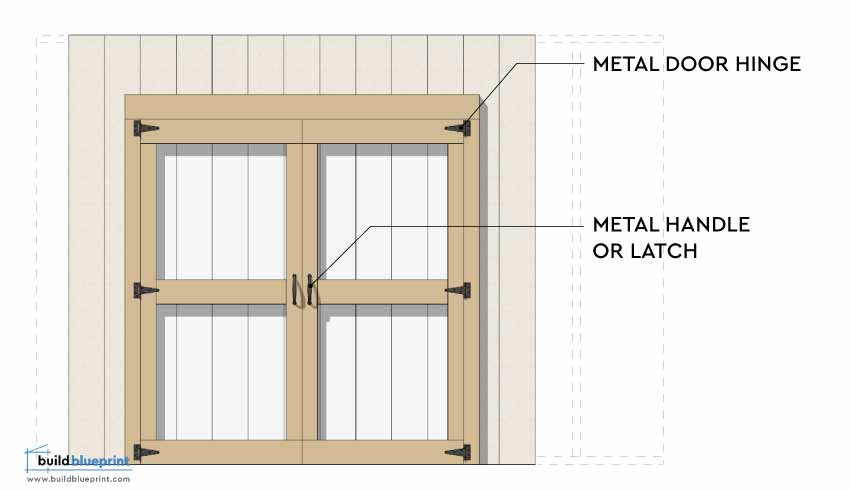

HARDWARE

2 – Door Handle or Latch

6 – 3-1/2 in. x 5/8 in. Door Hinge

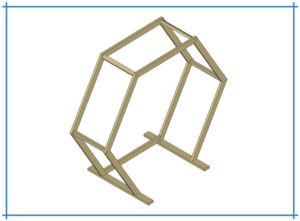

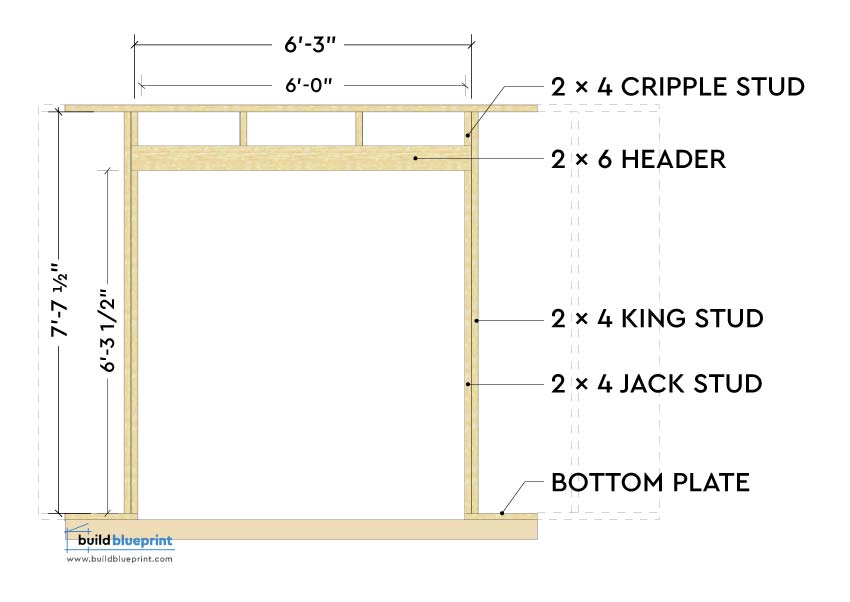

Step 1 – Door Framing

Start with building the door frame opening as illustrated below. Make sure the edges of the studs and header are perfectly flush, measure and adjust as needed.

Cut two 2 x 4 lumbers to 6′ 3 1/2″ length for jack stud.

Cut two 2 x 4 lumbers to 7′ 7 1/2″ length for king stud.

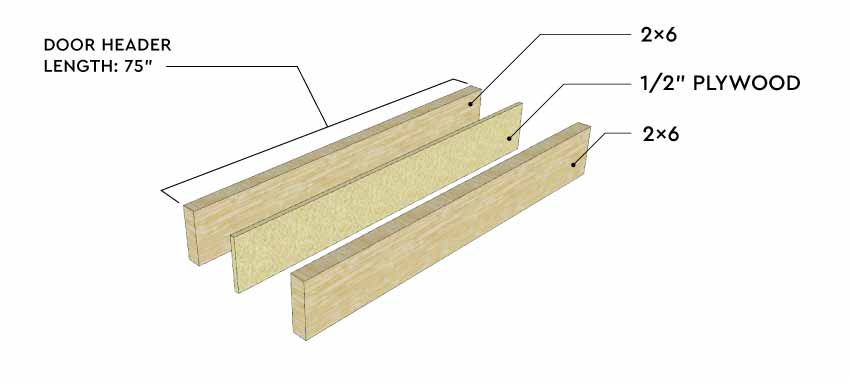

Cut two 2 x 6 lumbers to 6′ 3″ length for door header, use a 1/2″ plywood as filler in-between.

Then, drill pilot holes and insert 2 1/2″ screws every 10″ to secure everything.

Both 2 x 6 or 2 x 4 lumbers will work for the header, for larger doors I would recommend 2 x 6’s. Cut the 2 x 6 and 1/2″ plywood filler to length, then assemble with 3 1/2″ screws every 8″.

Step 2 – Add Exterior Siding

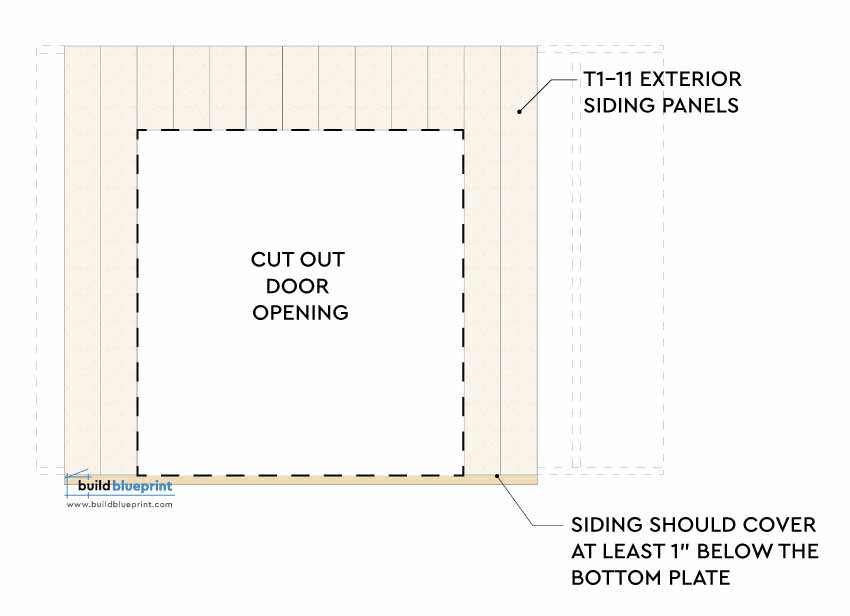

After the wall frame is set in place, install the T1-11 exterior siding panel with 2 1/2″ nails every 8″. The bottom of the siding should be at least 1″ below the bottom plate, this is to cover the gap between the wall frame and foundation.

Measure and cut out the door opening, use the jack stud framing as the guide. You can use a Sabre saw to cut through T1-11 fairly easily.

Step 3 – Install Casing

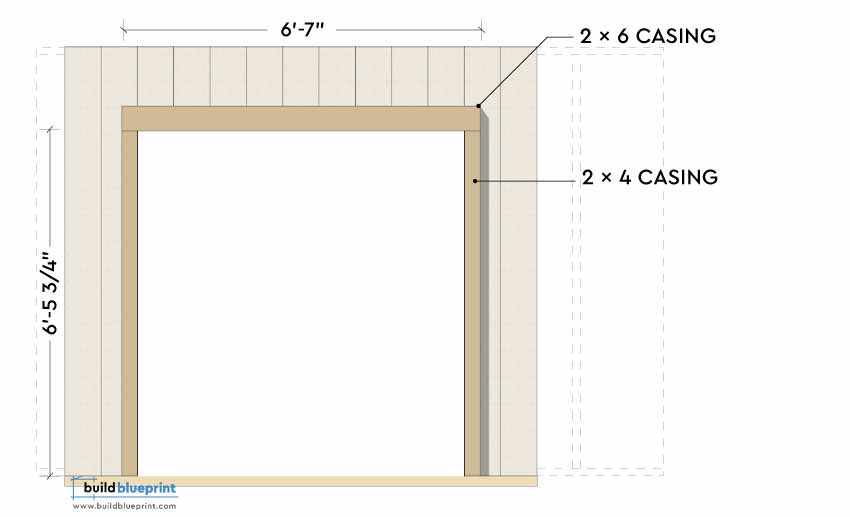

Cut a single 2 x 6 lumber to 6′ 7″, and cut two 2 x 4 lumber to 6′ 5 3/4″.

It’s important for the casings to flush with the door opening, so the door opens and closes smoothly. Drill pilot hole and insert 3 1/2″ screws to secure in place.

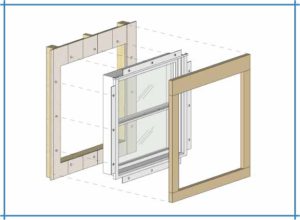

Step 4 – Door Construction

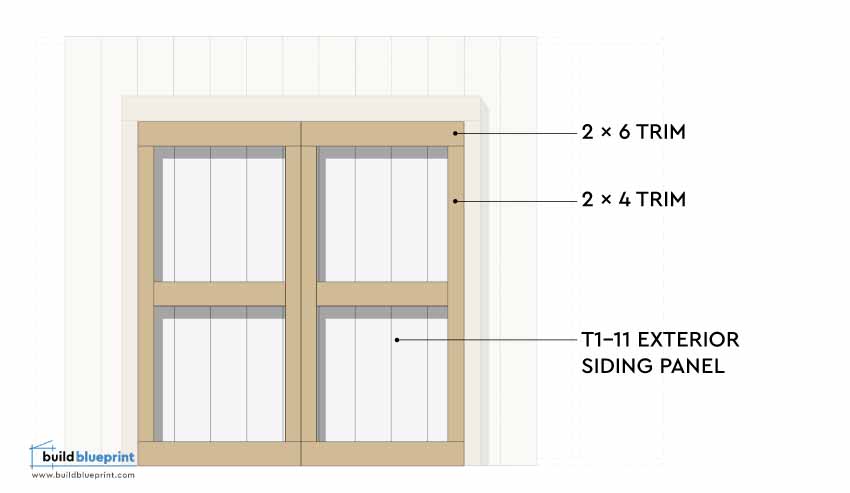

Finally, time to work on the actual doors! First, measure the door opening again to confirm height and width, sometimes this can change slightly from craftsmanship. Cut out both doors to size from a single piece of T1-11 exterior siding panel. Hold them up to make sure they fill the entire door opening without any sizable gaps.

Materials for one door: cut two 2 x 6 lumbers to 3′, cut a single 2 x 6 lumber to 2′ 5″, and cut two 2 x 4 lumbers to 5′ 6″.

Place trims flat onto the siding panel to ensure they are square. Then drill pilot holes and insert 2″ screws to secure in place. Repeat for the second door.

Step 5 – Hanging the Door

With both completed doors in closed position, use a pencil to mark up the metal hinge locations on both the door and the casing. Make sure the hinges are straight, yielding a smoother swing.

Attach the hinges onto the door with screws first. Then lift the door in place at closed position, screw in the hinges onto the casing. Swing the door to test out alignment, adjust as needed. Repeat for the second door.

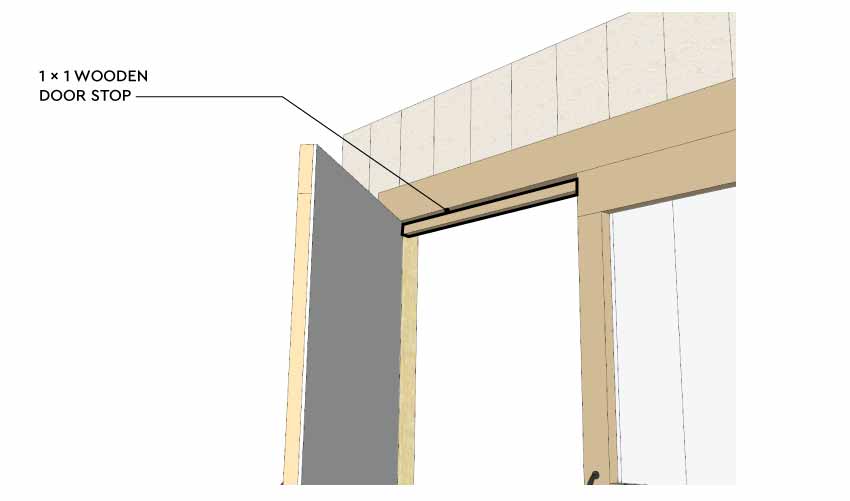

It is also recommended that you add a door stopper to prevent the doors from swinging into the shed. With the doors in closed position, attach any small piece of wood block (1 x 1) under the header. Make sure it’s tight against the back side of the doors in closed position, this will get the doors to close perfectly.

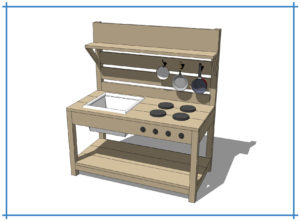

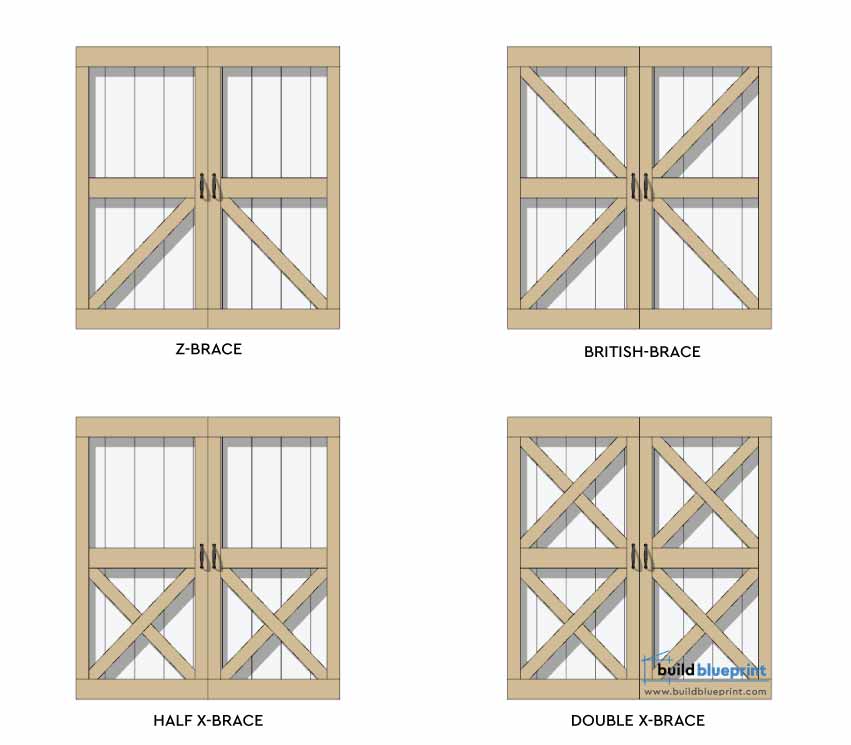

And that’s it, your double shed door is complete! If you’d like to get fancy, try some of the bracing trim patterns below:

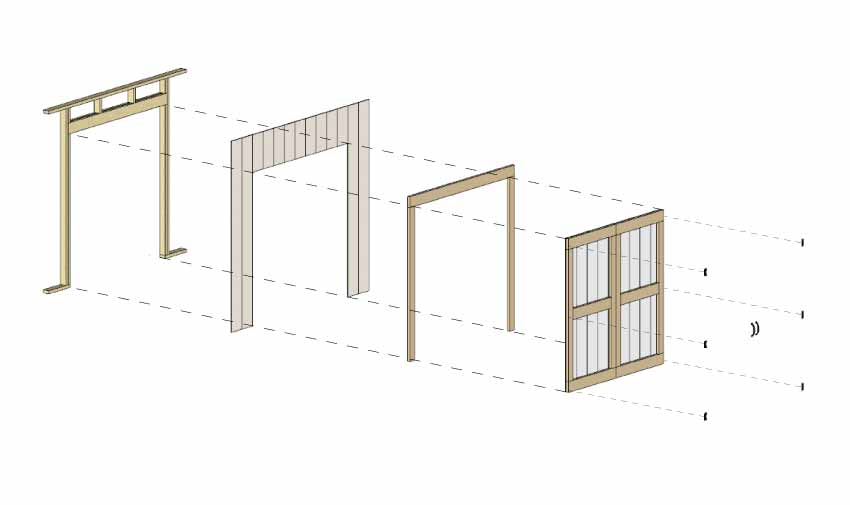

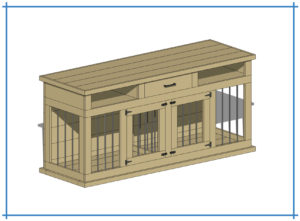

3D View of Double Shed Door Assembly